Lean Six Sigma Black Belt Training

Lean Six Sigma Black Belt Training and Certification is an advanced practitioner programme designed for experienced professionals who are expected to lead complex improvement initiatives and drive sustained performance change across teams, functions and processes.

Building on prior Green Belt knowledge, the programme develops deeper analytical capability, stronger change leadership skills and the confidence to address more complex, cross-functional challenges. You extend your ability to diagnose performance issues, evaluate improvement options and apply advanced tools and techniques in a range of real organisational scenarios.

For participants who completed Green Belt training some time ago, refresher modules are included to reinforce core concepts and close any gaps in knowledge, ensuring a strong and consistent foundation before progressing.

Advanced analysis is supported through the use of statistical software, including a Minitab trial version, with clear guidance provided upon enrolment so you are fully prepared to use the tools effectively during the programme.

All course content, learning resources, assessments and exams are supported with multilingual language capability, enabling participants to learn, collaborate and apply learning effectively across global and cross-functional environments.

By completing the Black Belt, you return to work equipped to lead high-impact improvement projects, manage resistance to change, coach others through structured problem-solving and contribute at a more strategic level to organisational improvement efforts.

How you benefit

![]() Lead complex, cross-functional Lean Six Sigma improvement initiatives using advanced DMAIC application

Lead complex, cross-functional Lean Six Sigma improvement initiatives using advanced DMAIC application![]() Apply advanced analytical and statistical tools to diagnose and validate performance issues

Apply advanced analytical and statistical tools to diagnose and validate performance issues![]() Drive sustainable improvement through structured change leadership and stakeholder engagement

Drive sustainable improvement through structured change leadership and stakeholder engagement![]() Coach and support Green Belts and project teams to improve delivery capability

Coach and support Green Belts and project teams to improve delivery capability![]() Translate data, analysis and insight into actionable business decisions

Translate data, analysis and insight into actionable business decisions

Participant Profile:

This Black Belt programme is suited to experienced improvement practitioners from manufacturing, service and transactional environments, including senior project and change managers, operational leaders, improvement specialists and consultants who are responsible for leading complex initiatives and influencing performance beyond a single team or function.

Participants are typically expected to take ownership of high-impact improvement work, support other practitioners and contribute to the wider deployment of continuous improvement capability within their organisation.

Course Pre-requisites

Prior Lean Six Sigma Green Belt certification or equivalent experience is required.

Exam and Certification

Online multiple-choice exam

50 questions

70 minutes

Pass mark: 70%

Successful completion results in Lean Six Sigma Black Belt certification.

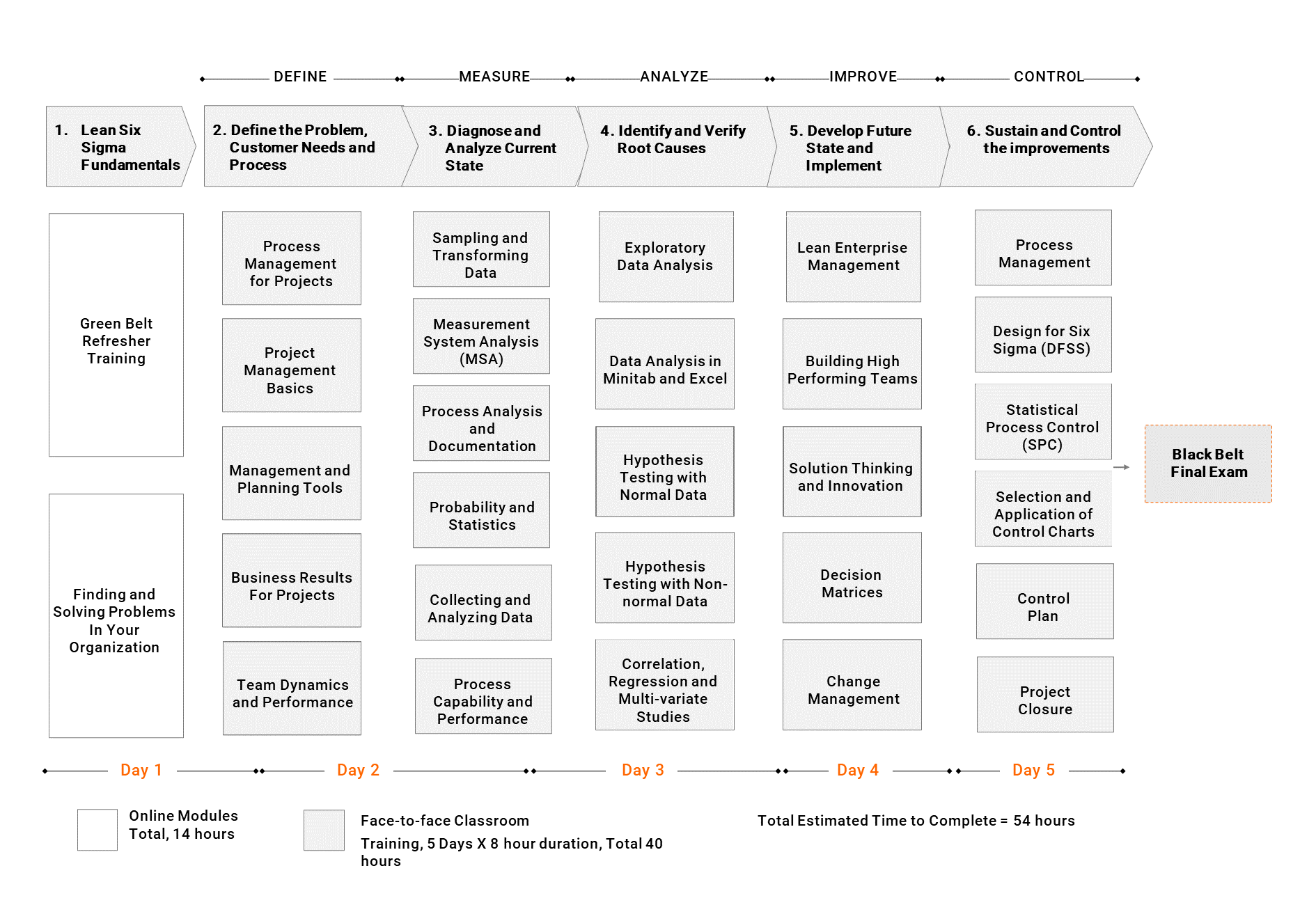

Intensive, immersive Black Belt training completed in five days.

The Black Belt Face-to-Face programme is designed for experienced practitioners who want the depth, pace and challenge of an immersive classroom environment. Delivered over five consecutive days, it allows you to complete your training in a focused, uninterrupted block, accelerating capability development without extending learning over months.

Led by an experienced Master Black Belt, the programme brings together professionals from diverse industries and organisational contexts. The classroom setting encourages challenge, debate and shared learning, enabling you to test ideas, compare approaches and learn from both the instructor and peers who are tackling real-world improvement and change challenges.

Learning is highly practical and deliberately demanding. Concepts are introduced in context and applied immediately through case material, exercises and facilitated discussion, reflecting how improvement leaders operate in practice. Emphasis is placed on judgement, interpretation and decision-making, particularly in situations involving ambiguity, resistance to change and competing priorities.

By the end of the five days, you leave with a strong command of advanced Lean Six Sigma methods, greater confidence in leading complex, cross-functional improvement initiatives, and a clear understanding of how to apply what you have learned back in your organisation. Assessment is completed through a final examination at the end of the programme, ensuring outcomes are consistent and robust.

Curriculum and Course Format

1.0 INTRODUCTION

Understand how lean and six sigma tools are applied to improve all types of processes in all types of enterprises: manufacturing, service, transactional, product and process design, innovation, etc.

Recognize key drivers for business (profit, market share, customer satisfaction, efficiency, product differentiation) and how key metrics and scorecards are developed and impact the entire organization.

1.1 Green Belt Refresher Training

1.2 Finding and Solving Problems in your Organisation

2.0 DEFINE

Define the scope and goals of the improvement project in terms of customer and/or business requirements, the process that delivers these requirements and stakeholder needs

2.2.1 |

Process elements |

2.2.2 |

Owners and stakeholders |

2.2.3 |

Identify customers |

2.3.1 | Collect customer data |

2.3.2 | Analyze customer data |

2.3.3 | Translate customer requirements |

2.4.1 | Building a Business Case & Project Charter |

2.4.2 | Project scope |

2.4.3 | Project metrics |

2.4.4 | Project planning tools |

2.4.5 | Project documentation |

2.4.6 | Project risk analysis |

2.4.7 | Project closure |

2.6.1 | Failure mode and effects analysis (FMEA) |

2.7.1 | Team stages and dynamics |

2.7.2 | Six sigma and other team roles and responsibilities |

2.7.3 | Team tools |

2.7.4 | Communication |

3.0 MEASURE

Calculate and interpret measures of dispersion and central tendency and construct and interpret frequency distributions.

Define and apply the concepts related to sampling (e.g., representative selection, homogeneity, bias, etc.) and select and use appropriate sampling methods (e.g., random sampling, stratified sampling, systematic sampling, etc.) that ensure the integrity of data. data.

Use various analytical methods (e.g., repeatability and reproducibility (R&R), correlation, bias, linearity, precision to tolerance, percent agreement, etc.) to analyze and interpret measurement system capability for variable and attribute measurement systems. Map the process and measure, understand and baseline the current process performance and capability through a set of relevant and robust measures.

Calculate process performance metrics such as defects per unit (DPU), rolled throughput yield (RTY), cost of poor quality (COPQ), defects per million opportunities (DPMO) sigma levels and process capability indices.

3.2.1 | Normality (Central Limit Theorem, P-values, Transforming Data) |

3.2.2 | Sampling Methods (Random and Process Sampling, Determining Sample Sizes, Selecting Samples) |

3.2.3 | EWMA Chart |

3.3.1 | Precision & Accuracy |

3.3.2 | Bias, Linearity & Stability |

3.3.3 | Gauge Repeatability & Reproducibility |

3.3.4 | Variable MSA |

3.4.1 | Process modeling |

3.4.2 | Process inputs and outputs |

3.5.1 | Drawing valid statistical conclusions |

3.5.2 | Central limit theorem and sampling distribution of the mean |

3.5.3 | Basic probability concepts |

| 3.6.1 | Types of data and measurement scales |

| 3.6.2 | Data collection methods |

| 3.6.3 | Techniques for assuring data accuracy and integrity |

| 3.6.4 | Descriptive statistics |

| 3.6.5 | Graphical methods |

| 3.6.6 | Probability distributions |

| 3.6.7 | Measurement System Capability |

distributions

3.6.7 Measurement System Capability

3.7.1 | Process capability studies |

3.7.2 | Process performance vs. specification |

3.7.3 | Process capability indices |

3.7.4 | Process performance indices |

3.7.5 | Short-term vs. long-term capability |

3.7.6 | Process capability for attributes data |

4.0 ANALYZE

Drawing valid statistical conclusions by distinguishing between descriptive and inferential studies and population and sample statistics.

Measuring and modelling relationships between variables to set-up and run hypothesis tests and correlation and regression analysis.

4.2.1 | Classes of Distributions |

4.2.2 | Inferential Statistics |

4.2.3 | Understanding Inference |

4.2.4 | Sampling techniques & uses |

4.2.5 | Central Limit Theorem and the principal correlations |

4.2.6 | Data Transformation, Box Cox |

4.4.1 | General Concepts & Goals of Hypothesis Testing |

4.4.2 | Significance; Practical vs. Statistical |

4.4.3 | Risk; Alpha & Beta |

4.4.4 | Hypothesis Testing of Means, Variances and Proportions ( Z- , p- and t-tests) |

4.4.5 | 1 & 2 sample t-tests |

4.4.6 | 1 sample variance |

4.4.7 | Paired-comparison tests |

4.4.8 | Single-factor analysis of variance (ANOVA) |

4.4.9 | Tests of Equal Variances. Including Tests of Equal Variance, Normality Testing and Sample Size calculation, performing tests and interpreting results. |

4.5.1 | Mann-Whitney |

4.5.2 | Kruskal-Wallis |

4.5.3 | Mood’s Median |

4.5.4 | Sample Sign |

4.5.5 | Sample Wilcoxon |

4.5.6 | One and Two Sample Proportion |

4.5.7 | Chi-Squared (Contingency Tables)a. Including Tests of Equal Variance, Normality Testing and Sample Size calculation, performing tests and interpreting results. |

4.6.1 | Simple linear correlation and regression |

4.6.1 | Simple linear correlation and regression |

5.0 IMPROVE

Apply divergent thinking by using creativity techniques to identify innovative solutions.

Use various tools and techniques for reducing cycle time, including continuous flow, single-minute exchange of die (SMED), etc.

How to make data driven project decisions Build High Performing Teams for project success How to Manage Resistance to Change

5.2.1 | Pull: Takt Time and Line Balancing, Kanban, Supermarket |

5.2.2 | Flow: Batch Reduction, Parallel Processing, Standard Work & Multi skilling, Modular Design, Layout & Cells, Quick Changeover (SMED), Level Scheduling |

5.2.3 | Steps to Perfection, Operational Equipment Effectiveness (OEE), Bottlenecks, Total Productive/Preventative Maintenance (TPM) |

5.2.4 | Assumption Busting the status quo |

6.0 CONTROL

Application of Six Sigma Design for Six Sigma (DFSS) Methodology to drive growth through innovation. Application of statistical process control (SPC) including control chart selection for monitoring and controlling process performance, tracking trends, runs and identifying special and common causes using rules for determining statistical control. Develop a Control Plan to emmbed Process Management principles

6.4.1 | Objectives and benefits |

6.4.2 | Rational subgrouping |

6.5.1 | −R, |

6.5.2 | −s, individuals and moving range (ImR / XmR), median |

6.5.3 | p, np, c, and u chart |

6.5.4 | Analysis of control charts |

Quizzes Segmented and embedded during and at the end of each DMAIC Phase

Final Exam Lean Six Sigma Black Belt Certification

Next Course Dates

E-Learning Modules

14 Hours

Face-to-Face Classroom Training 5 Day x 8 Hours

40 Hours

United Kingdom

20 -24th April 2026

Portugal

This blended course is run jointly with Instituto Superior Técnico and Erising.

Session 1

(2 Day Face-to-Face or Remote) – 17th and 18th Nov 2025

Daily Timing: 09:00 – 17:00

Venue: Instituto Superior TécnicoSession 2 (Remote) – Thu 27th Nov 2025

Session 3 (Remote) – Thu 4th Dec 2025

Session 4 (Remote) – Thu 11th Dec 2025

All remote sessions timing 08:30 – 14:30 Hrs. (6 hrs per session)

Classroom training sessions take place in-person between 09:00 to 17:00 BST / 08.00 to 16:00 UTC

Estimated time to complete

54 Hours

Course Duration

5 Days

Course Fee (excluding VAT)

£ 2,695

What's Included

- Five days of intensive, face-to-face classroom training delivered by a Master Black Belt

- Immersive classroom learning with experienced practitioners from diverse industries

- 12 months access to the Black Belt Bootcamp platform, including advanced tools, case studies and resources

- Green Belt refresher modules included to ensure a consistent starting point

- Black Belt final exam and electronic certificate

- Ongoing tutor support and peer discussion

- Access to a global Lean Six Sigma learning community

The quickest, easiest and most engaging way for individuals and companies to get on track with Lean Six Sigma concepts and tools.

In-person and virtual workshops

Ready-to-use job aids, tools and templates

Peer-to-peer learning forums

Distinctive digital learning content

Expert coaching support

Nudges, reminders and micro learning

Excellent for remote teams

Auto-translate curriculum and instruction

Multi-channel; eLearning, virtual, face-to-face or in-house

Make progress in less time and deliver results quickly

Tailored learning solutions for companies

Mobile friendly

Highly practical

Join our Lean Six Sigma community

Practice exams

World Class Lean Six Sigma Certification

Complete your Black Belt through immersive classroom learning