Lean Six Sigma Green Belt Training and Certification is a practitioner-level programme designed for professionals who are expected to lead defined improvement projects and deliver measurable performance improvement within their area of responsibility.

The programme builds a strong working foundation in Lean and Six Sigma principles and applies them through the Define–Measure–Analyse–Improve–Control (DMAIC) framework. You develop the capability to scope improvement opportunities, analyse process performance, use data to support decisions, manage change locally and implement improvements that deliver sustainable results.

All course content, learning resources, assessments and exams are supported with multilingual language capability, enabling participants to learn, collaborate and apply tools effectively across global and cross-functional environments.

By completing the Green Belt, you return to work equipped to lead structured improvement projects end-to-end, contribute confidently to organisational performance goals and support the development of a continuous improvement culture within your team or function.

How you benefit

![]() Lead structured Lean Six Sigma improvement projects using the DMAIC framework

Lead structured Lean Six Sigma improvement projects using the DMAIC framework![]() Apply practical tools to improve quality, efficiency, cost and customer experience

Apply practical tools to improve quality, efficiency, cost and customer experience![]() Use data and analysis to diagnose problems and make confident decisions

Use data and analysis to diagnose problems and make confident decisions![]() Identify waste, manage variation and address root causes of performance gaps

Identify waste, manage variation and address root causes of performance gaps![]() Build the capability to sustain improvements within your team or function

Build the capability to sustain improvements within your team or function

Participant Profile

This Green Belt programme is suited to professionals from manufacturing, service and transactional environments, including team members, supervisors, project and change managers, functional specialists, consultants and leaders who are expected to contribute to or lead improvement initiatives. Group and team participation is supported, including action learning projects aligned to organisational priorities.

Course Pre-requisites

An interest in developing practitioner-level continuous improvement capability.

Exam and Certification

Online multiple-choice exam

30 questions

40 minutes

Pass mark: 70%

Successful completion results in Lean Six Sigma Green Belt certification.

This Virtual Classroom format combines the structure and discipline of instructor-led training with the flexibility of remote delivery. It is designed for professionals who want real-time interaction, guided learning and accountability, without the need to travel or step away from work for extended periods.

Delivered live by an experienced Master Black Belt, the programme runs through a series of interactive virtual workshops. Sessions are paced to ensure concepts are understood, applied and reinforced, with time between workshops to reflect and begin applying learning in your own work environment.

Unlike self-paced learning, the Virtual Classroom creates a shared learning journey. You learn alongside other professionals, engage in live discussion, ask questions as they arise and benefit from facilitator insight drawn from real organisational improvement projects.

Key benefits of the Virtual Classroom format

- Live instruction and facilitation by an experienced Master Black Belt

- Real-time interaction, discussion and Q&A

- Structured learning schedule that maintains momentum and focus

- Peer learning with professionals from a range of industries

- Time between sessions to reflect and apply learning in the workplace

- Full access to the Green Belt Bootcamp platform and learning resources

The Virtual Classroom is ideal for professionals who value guided learning, interaction and structure, but who need the flexibility of remote attendance. It works particularly well for individuals who prefer to learn through discussion and explanation, as well as organisations looking to train geographically dispersed teams together.

This format combines self-paced eLearning with live, instructor-led virtual sessions, giving you flexibility without losing structure or depth. Core concepts and tools are introduced online, allowing you to prepare at your own pace and revisit topics as needed.

Online preparation feeds directly into the live sessions, so virtual classroom time is used for discussion, application and deeper understanding rather than passive learning.

Online learning includes:

- Purpose-built instructional videos

- Interactive exercises and quizzes

- Case studies and practical resources

- Guided discussions supported by Master Black Belts

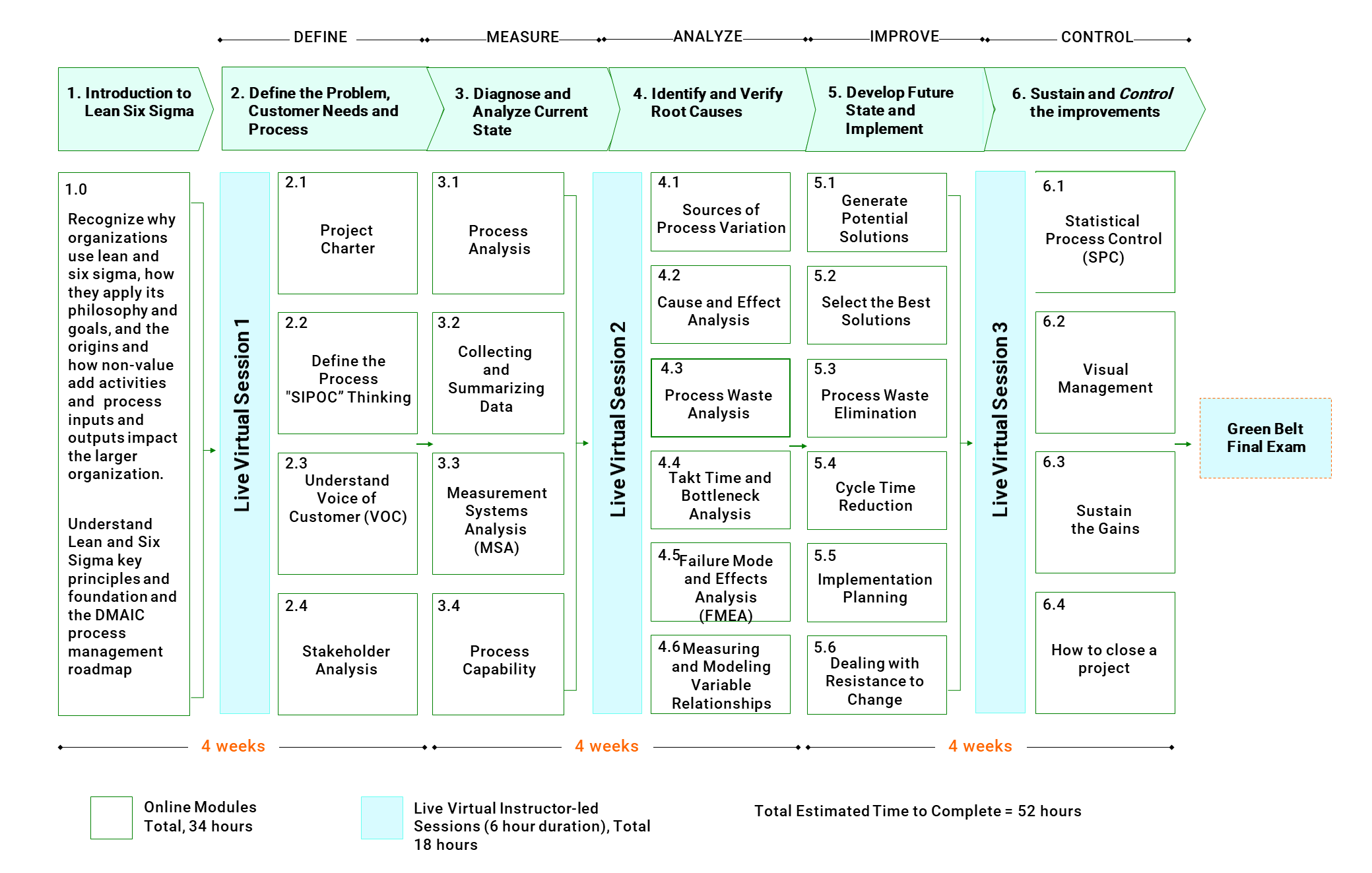

You complete approximately 34 hours of online learning, structured into manageable blocks around professional commitments.

The programme follows the DMAIC methodology, enabling you to apply learning as you progress rather than waiting until the end. Tools and techniques are introduced in a practical sequence, helping you shape improvement ideas early and refine them as your capability grows.

By combining continuous access to learning materials with live discussion and peer input, you develop solutions that are relevant to your organisational context.

By the end of the programme, you will be able to apply Lean Six Sigma tools to real improvement initiatives, set clear priorities and action plans, and confidently contribute to or lead improvement projects.

Curriculum and Course Format

1.0 INTRODUCTION TO LEAN SIX SIGMA

5 hours

Understand the value of lean and six sigma, its philosophy, history and goals and the rationale for combining the lean and six sigma approaches to apply to improvement projects.

Understand lean six sigma principles and foundation and the Define-Measure-Analyze-Improve-Control (DMAIC) process management roadmap.

Understand how non-value add activities and process inputs and outputs impact the larger organization.

1.01 Six Sigma DMAIC Overview

1.02 Process Variation

1.03 Six Sigma and Organizational Goals

1.04 The DMAIC Process Management Roadmap

1.05 Belt Structure for Skills Development

1.06 Summary – Six Sigma DMAIC Overview

1.07 Introduction to Lean

1.08 The Origin of Lean

1.09 Foundations of Lean

1.10 Value-add and Non-value-add Activities

1.11 Lean Mindset and Thinking

1.12 Summary – Introduction to Lean

1.13 Integration of Lean and Six Sigma to drive On- Time, On-Quality and On Cost performance

2.0 DEFINE

4 hours

Define the scope and goals of the improvement project in terms of customer and/or business requirements, the process that delivers these requirements and stakeholder needs.

2.01 Overview – Define Phase

2.02 Problem Definition and Project Charter

2.03 Define the Process – SIPOC Thinking

2.04 Understand Voice of Customer (VOC)

2.05 Customer Identification

2.06 Gather Customer Feedback

2.07 Analyze VOC Data

2.08 Define What is Critical to Quality (CTQ)

2.09 Summary – Understand Voice of Customer (VOC)

2.10 Stakeholder Analysis

2.11 Summary – Define Phase

3.0 MEASURE

6 hours

Map the process and measure, understand and baseline the current process performance and capability through a set of relevant and robust measures.

Calculate process performance metrics such as defects per unit (DPU), rolled throughput yield (RTY), cost of poor quality (COPQ), defects per million opportunities (DPMO) sigma levels and process capability indices.

3.01 Overview – Measure Phase

3.02 Process Analysis

3.03 Collecting and Summarizing Data

3.04 Types of Data and Measurement Scales

3.05 Evaluating Metrics

3.06 Data Collection Methods

3.07 Sampling Methods

3.08 Descriptive Statistics

3.09 Graphical Techniques

3.10 Summary – Collecting and Summarizing Data

3.11 Measurement Systems Analysis (MSA)

3.12 Process Capability

3.13 Process Capability Indices

3.14 Process Performance Indices

3.15 Short-term and Long-term Capability

3.16 Process Capability for Attribute data

3.17 Process Performance vs. Specification

3.18 Summary – Process Capability

3.19 Summary – Measure Phase

4.0 ANALYZE

6 hours

Analyze the gap between the current and desired performance, prioritise problems, process risk and identify root causes and understand / statistically verify their effect on process performance.

4.01 Overview – Analyze Phase

4.02 Sources of Process Variation

4.03 Cause and Effect Analysis

4.04 Process Waste Analysis

4.05 Takt Time and Bottleneck Analysis

4.06 Failure Mode and Effects Analysis (FMEA)

4.07 Measuring and Modeling Variable Relationships

4.08 Input and Output Variables

4.09 Correlation

4.10 Regression

4.11 Summary – Measuring and Modeling Variable Relationships

4.12 Summary – Analyze Phase

5.0 IMPROVE

4.5 hours

Generate, select and implement improvement solutions to fix the problems and prevent them from re-occurring so that the required performance goals are met.

Use concepts such as value chain, flow, pull, perfection, etc., and tools commonly used to eliminate waste, including kaizen, 5S, A3 problem solving, morning meetings etc.

5.01 Overview – Improve Phase

5.02 Generate Potential Solutions

5.03 Select the Best Solutions

5.04 Process Waste Elimination

5.05 Cycle Time Reduction

5.06 Implementation Planning

5.07 Dealing with Resistance to Change

5.08 Summary – Improve Phase

6.0 CONTROL

4.5 hours

Implement the improved process / solutions in a way that sustains and “holds the gains “and the process has robust control measures and a response plan.

The objectives and benefits of statistical process control (SPC) to track process performance and identify special and common causes.

6.01 Overview – Control Phase

6.02 Sustain the Gains

6.03 Documentation

6.04 Monitor Performance

6.05 Lessons Learned

6.06 Visual Management

6.07 Statistical Process Control (SPC)

6.08 How to close a project

6.09 Summary – Control Phase

Quizzes Segmented and embedded during and at the end of each DMAIC Phase

3.5 hours

Final Exam Lean Six Sigma Green Belt Certification

0.6 hours

Total Estimated Time to Complete Green Belt Training & Certification:

34 hours

Next Course Starting in

E-Learning Modules

34 Hours

Instructor-led Live Virtual Sessions

18 Hours

Dates

16th Feb 2026

23rd Feb 2026

2nd Mar 2026

Virtual Instructor-led sessions take place live via Zoom between 09:30 to 15:30 BST / 08.30 to 14:30 UTC

Estimated time to complete

52 Hours

Course Fee (excluding VAT)

£ 1,875

What's Included

- 34 hours of structured self-paced eLearning with integrated quizzes and DMAIC roadmaps

- 18 hours of live instructor-led virtual classroom sessions delivered by a Master Black Belt (3 x 6-hour sessions)

- 12 months access to the Green Belt Bootcamp learning platform, including toolkits, case studies and downloadable resources

- Green Belt online exam and electronic certificate

- Unlimited practice exams and free resits

- Tutor support via discussion groups and messaging

- Access to a global Lean Six Sigma learning community

The quickest, easiest and most engaging way for individuals and companies to get on track with Lean Six Sigma concepts and tools.

In-person and virtual workshops

Ready-to-use job aids, tools and templates

Peer-to-peer learning forums

Distinctive digital learning content

Expert coaching support

Nudges, reminders and micro learning

Excellent for remote teams

Auto-translate curriculum and instruction

Multi-channel; eLearning, virtual, face-to-face or in-house

Make progress in less time and deliver results quickly

Tailored learning solutions for companies

Mobile friendly

Highly practical

Join our Lean Six Sigma community

Practice exams

World Class Lean Six Sigma Certification